On-site stormwater detention; and it's made from recycled yoghurt containers.

On-site detention installations are designed to deliver water slowly and safely to council kerbs, street systems and drainage, to keep the stormwater infrastructure from becoming overwhelmed – causing flooding.

EcoBloc SMART tanks can be designed to create effective on-site detention systems for many developments.

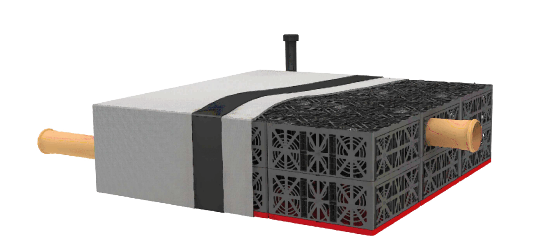

Detention tanks have inlet and outlet connections, specified as needed for the safe release of water at a speed that the surrounding infrastructure can handle.

Assembling an EcoBloc detention system in very similar to infiltration system in terms of the EcoBloc parts.

In detention tank, after an excavation of the pit and compaction of the base, the installation team lay an outer layer of geotextile, followed by a geomembrane layer or liner, then an inner layer of geotextile, to isolate the system from its surroundings and from groundwater. The EcoBloc SMART base plates are assembled according to the design of the tank, then, EcoBloc modules are clipped together to make sure every EcoBloc is secure, making the tank a strong structure, and end plates are connected to the lateral surfaces of the completed tank.

The final step includes welding the geomembrane all around the tank and making sure the tank can detain stormwater from the development.